Global carbon dioxide (CO2) reduction is unquestionably the most significant global challenge of this century. The goal of achieving carbon neutrality by 2050 and limiting the long-term increase in global average temperature to 1.5°C has remained unchanged since the signing of the historic Paris Agreement in 2015.

Achieving this lofty objective requires the energy sector to prioritize renewable energy over fossil fuels.

A large part of this change involves the automotive field, pushing car makers toward reducing the production of Internal Combustion Engine (ICE) vehicles. As shown in Figure 1, IHS projects Electric Vehicles (EV) are taking an increasing share of the automotive sector and will overtake ICEs from 2026.

This EV production estimation includes pure-electric vehicles, Hybrid EVs (HEVs), and Plug-in Hybrid (PEVs). A pure electric vehicle is powered exclusively through electric motors, an HEV combines both a conventional ICE system with an electric propulsion system, and a PEV is any vehicle that can be recharged from any external source of electricity.

Enabling vehicle electrification and digitalization

Because its energy is stored in batteries, the key characteristics of xEVs are related to efficiency, safety, and reliability.

Improving the technology to deliver better performance, new features, and miniaturization, all the devices designed with STMicroelectronics’ VIPower are enablers for vehicle electrification and digitalization, providing intelligent power switches to drive high- and low-sided loads and electric motors with very low losses and high current sense accuracy.

In EVs, all the electronic devices play a primary role. As a result, improvement increases quality and reliability: from an actual failure rate of 0.08 parts per million (Figure 2), the next goal for VIPower is to be a zero-defects technology.

High voltage on xEV: a risk for occupants’ safety?

Failures in the vehicle’s electronics and the charging infrastructure could cause significant safety issues for both occupants and third parties. Accordingly, all EVs are required to have the power electronics securely connected to the HV battery.

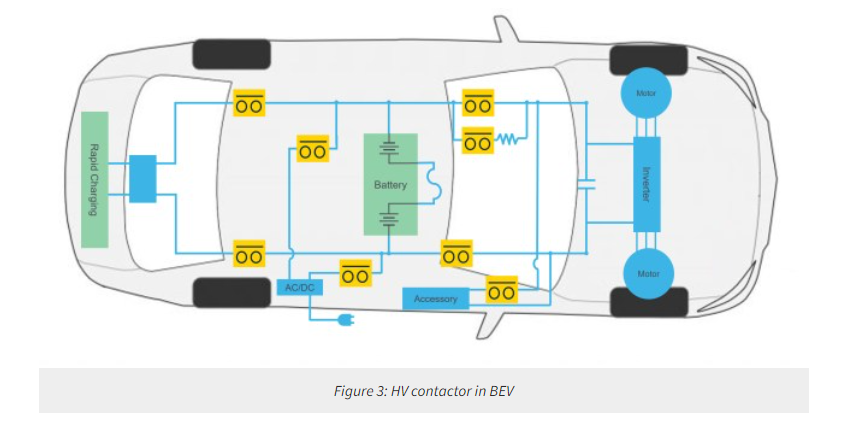

For these connections, manufacturers use HV contactors (Figure 3). They are electromechanical switches ideal for connecting to high current and high voltage loads. Unlike relay, HV contactors are intended to sustain high current loads.

Two main contactors and one precharge contactor are implemented in all the EVs, starting from basic hybrid electric vehicles to pure electric ones. The main contactors are used to connect or disconnect the battery pack to power electronics; they can disconnect very quickly in the event of an accident. A second contactor – a precharge contactor – is needed before closing the main contactor to charge an initially discharged DC link capacitor, avoiding in-rush current that can damage the battery and the loads.

Battery Electric Vehicles (BEVs) use utilize contactors in both the AC/DC charge and in the DC/DC fast-charge equipment, as well as in the accessory domain (Figure 3).

Summing up, there are 8 HV contactors in BEVs, 5 in PHEVs, and 3 in HEVs.

Quality and reliability: VIPower devices as HV contactor driver to increase system robustness

A contactor, as shown in Figure 4, consists of two iron cores. One core is fixed and surrounded by an insulated copper coil and another movable one. A control voltage applied on the coil creates a magnetic field that attracts the movable iron core to the fixed one, connecting the power lines to the load.

To close the contactor, Figure 5 shows the typical coil current profile in three phases:

● Pickup phase: the current is large enough and maintained long enough to ensure the contactor is closed. This time is typically on the order of hundreds of milliseconds.

● Hold phase: the current is less than necessary in the pickup phase and reduces power consumption while efficiently keeping the contactor closed. This phase can last for an undefined time, up to hours.

● Fast decay: the current drops very quickly, over about 10ms, to ensure a fast opening that increases the contactor’s reliability and lifetime.

Figure 6 shows a typical circuit topology implemented to drive an HV contactor. It is a discrete solution built from high-side drivers and low-side drivers, based on VIPower technology that provides control, protection, and diagnostics.

The high-side driver monitors the current profile to properly drive the HV contactor, while the low-side driver is driven using PWM to modulate the load current profile.

Both high-side and low-side drivers are needed to protect the HV contactor against short circuit vs GND and Battery and to achieve proper safety levels.

VNH7100BAS: a Fully integrated solution also for HV contactor

The VNH7100BAS is a full bridge for DC motor drivers. Designed in VIPower technology, it incorporates a dual monolithic high-side and two low-side switches in an SO-16N package on an electrically isolated lead-frames. The VNH7100BAS embeds several diagnostics (current sense, diagnostic in off state, and temperature monitoring) along with protection circuits (power limiting, current limiting, over-temperature, and cross-current protections). Combined these diagnostic and protection circuits allow designers to deliver safe sensitive applications with a high level of reliability and miniaturization.

Moreover, the VNH7100BAS is suitable as a new and innovative solution for driving HV contactors (Figure 7).

In this case, the VNH7100BAS includes all the functions to properly control, monitor, and protect the HV contactor, including the features of current recirculation during PWM and fast demagnetization, in a single IC.

The 3 phases of HV contactor current profiles in Figure 5 can be implemented as follows:

● Pickup-phase: driving the device in clockwise mod, setting HSA and LSB on.

● Hold phase: enabling the PWM on LS.

● Fast decay: inverting the polarity on the coil, setting only HSB on.

Therefore, the VNH7100BAS decreases the PN count in the final application, resulting in a smaller PCB footprint. Moreover the embedded monitor and protection functions enhance safety and reliability.

About US

Heisener Electronic is a famous international One Stop Purchasing Service Provider of Electronic Components. Based on the concept of Customer-orientation and Innovation, a good process control system, professional management team, advanced inventory management technology, we can provide one-stop electronic component supporting services that Heisener is the preferred partner for all the enterprises and research institutions.